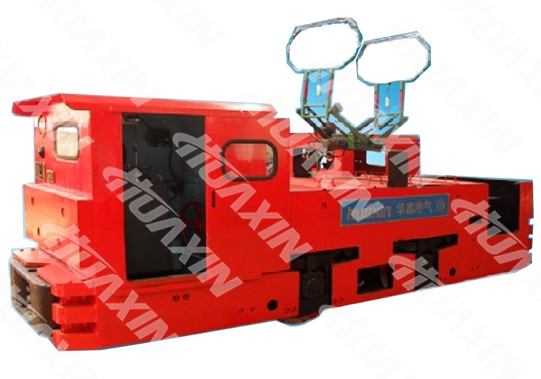

Explosion-proof Special Battery Power Supply Device

The power supply device can be taken as a DC power supply for the Mining Explosion-proof Special Battery Electrical Locomotive.

Technical Parameters

2.1 Basic Technical Parameters (see Table 1 and Table 2)

Table I Basic Technical Parameters of the Power Supply Device

Model of Power

Supply Device

Rated

Voltage (VDC)

Rated

Capacity (Ah)

Maximum Overall Dimensions (mm)

Weight (kg)

Length

Broadband

High

Without

Solution

With

Solution

DXT-90/330

90

330

1929

1000

567

1270

1607.5

DXT-48/330

48

330

1000

915

567

760

940

DXT-140/440

140

440

2800

1050

500

1900

2565

DXT-192/560

192

560

2670

1050

620

3376

4096

Table II Basic Technical Parameters of the Monomer Battery

Battery Model

Rated Voltage (VDC)

Rated Capacity (Ah)

Maximum Overall Dmensions (mm)

Weight (kg)

Length

Broadband

High

Without Solution

With Solution

D330KT

2

330

137

181

460

15

22.5

D440KT

2

440

208

160

374

19.5

29

D560KT

2

560

145

163

575

25

33.5

2.2 Discharge Performance (see Table 3)

Table 3 Discharge Performance

Battery

Model

5 Hour Rate

3 Hour Rate

1 Hour Rate

Final voltage of discharging 1.70V

Current (A)

Capacity (Ah)

Current (A)

Capacity (Ah)

Current (A)

Capacity (Ah)

D330KT

66

330

91

237

330

165

D440KT

88

440

122

366

264

264

D560KT

112

560

155

465

336

336

2.3 Charging Performance (see Table 4)

Table 4 Charging Performance

Battery Model

Initial Charging

Common Charging

Stage I

Stage II

Current (A)

Time (h)

Current (A)

Time (h)

Current (A)

Time (h)

D330KT

45-50

25-30

23-26

45-50

50-60

12-14

D440KT

45-50

25-30

23-26

45-50

50-60

12-14

D560KT

55-60

25-30

30-35

45-50

60-70

12-14

The Explosion-proof Special Power Supply Device consists of a special lead-acid battery, a battery box, connecting wires and a mining explosion-proof male pin connector, which can be used with the Explosion-proof Special Battery Electrical Locomotive in coal mines full with methane or coal dust explosion hazard.

1. The product is an Exsl Mining Explosion-proof Special Model. The structure performance conforms to the requirements in MT/T334-2008, GB10978-89 and GB3836.1-2000, and is appraised by related explosion-proof inspection station authorized in China.

2. The product mainly consists of a glass fiber tubular anode plate, a paste negative plate, a micro rubber or plastic partition board, an ethylene-propylene copolymer plastic battery jar, a battery cover and sulfuric acid electrolyte. Body hot-melt sealing is adopted for the battery jar and battery cover.

3. When the unit cells are combined into a battery pack, a special wire is used for soldering connection to reduce the contact resistance and prevent the spark from being generated, ensuring the safety of the use and the good wire connection of the battery pack under special circumstances.

4. In order to avoid short circuit of the battery pack, the exposed position of the electrical conductor shall be covered with insulated plastic sheath.

5. Sealant is applied on the casting interface of the connecting wire, so as to prevent corrosion of sulfuric acid, and guarantee safe use.

6. The acid-resistant special working plug is adopted for the battery, and is subject to hydrophobic treatment, so as to guarantee good air permeability of the battery, and reduce water consumption of electrolyte.

1. It is applicable for roadway with gas and coal dust explosion hazard.

2. The elevation shall not exceed 1,200m.

3. The maximum ambient temperature shall be 40℃/140℉, and the minimum shall be -20℃/-4℉.

4. The monthly average maximum relative humidity of the wettest month shall be less than 95% (the monthly average minimum temperature of the same month shall not be higher than 25℃/77℉).

5. No gas or conductive dust in the air enabling to cause corrosion to metal or damage insulation.

6. The maximum acceleration of impacts in the longitudinal direction of the electrical locomotive shall be no more than 30m/s2.

7. The narrow-gauge track roadbed and the turnout laying quality shall conform to provisions in GBJ213 Article 328: Safety Rules for Coal Mine.

-

About Huaxin

-

Follow Us

-

Share Us

©1996-2017 晋ICP备07500050号 Huaxin Copyright

©2016-2017 晋ICP备07500050号 Huaxin Copyright