Hello, welcome to Huaxin

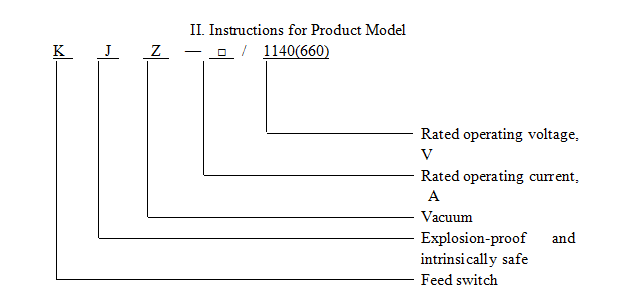

Mining Explosion-proof and Intrinsically-safe Vacuum Feed Switch

1.The Mining Explosion-proof and Intrinsically-safe Vacuum Feed Switch (hereinafter referred to as Switch) are mainly used in explosion gas environments that are containing mixture of methane and coal dust in coal mines and other surrounding areas. It works at AC 50Hz, rated voltage 660V or 1140V, currents of 630A, 400A, 200A and below as the main switch or sub-switch of a power distribution system, it can also be used as a switch of a large-capacity motor for infrequent start-up.

2.This switch uses a ZBK-3TE microcomputer monitoring and protection device as the core control unit, which integrates short circuit protection, overcurrent protection, leakage protection, selective leakage, leakage blocking, undervoltage protection, wind power blocking, gas off lockout, and communication interface. When the protection works normally, it can display the operating voltage and the operating current of the power grid, and the setting value of the operating current of the switch in Chinese. When there is short-circuit, over-current, leakage current, under-voltage, or gas concentration exceeding the limit and other error occurring in the circuit, the circuit will be automatically cut off. The cause of the fault will be displayed and memorized. At the same time, the switch will be locked. Only after the fault is cleared and manual reset is performed, the switch can be closed and transmit power. The switch also has analog test functions for leakage current, overcurrent, undervoltage, and leakage lockout. When it is used as the main switch, it has three-phase symmetry leakage and leakage protection, and it is the backup protection for sub-switch leakage protection; when it is used as a sub-switch, it has selective leakage protection and leakage lock protection function.

1. Rated Voltage: 1140V, 660V

2. Rated Current: 630A, 400A, 200A

3. Intrinsically-safe Parameters: Um: 140V AC Uo: 6V Io: 0.43A Co: 100uF Lo: 0.2mH

4. Power Frequency: 50Hz

5. Electrical Life: 15,000 times

6. Mechanical Life: > 30,000 times

1.The Feed Switch adopts an innovative translational quick-opening type explosion-proof housing. It is small in size (modularized), and has a compact and reasonable internal structure, simple and reliable operation, and explosion-roof performance in accordance with GB3836.2 the Electrical Equipment for Explosive Gas Environments - Part 2 “ Explosion-proof type 'd' Requirements”.

2.The advanced microprocessor and large-capacity new chip are adopted for the protector, plus high-precision data processing and advanced protection algorithm, the protection precision is high, and the reaction speed is fast. It has multiple protection functions, such as short circuit (two kinds of protection: phase-sensitive protection and current amplitude protection), overload, electrical degree measuring, overvoltage, under-voltage, three-phase unbalance, phase failure, electric leakage locking, leakage protection, selective leakage protection, wind power locking, gas locking, etc.

3. Full Chinese display of current time, three-phase currents and electricity grid voltage, insulation resistance, closing and opening state, error information, etc.

4. RS-485 or CAN communication interface can be equipped for connection with the monitoring system according to users' demands.

5. The communication interface and the remote control circuit is intrinsically safe, and conformed to the requirements in GB3836.4 Electrical Equipment for Explosive Gas Environments - Part 4: Intrinsic Safety 'i'.

The overall structure of the protective case consists of the explosion-proof primary chamber and wiring chamber.

1. The explosion-proof primary chamber consists of the front door, chamber, rear explosion-proof flange, etc.

a) The front door is provided with an easy-to-observe Chinese display window and operation buttons such as closing, opening, resetting, overloading, leakage, shifting, confirming and adjusting.

b) The chamber is equipped with PLC protection devices and various protection signal sampling components.

c) The explosion-proof flange at the rear of the explosion-proof chamber can be subject to flange connection with the wiring chamber of the mobile substation (dry-type transformer).

2. Three terminals of the main circuit and two seven-core terminals for control loop wiring shall be installed in the wiring chamber. There are two pressure plate cable lead-in devices at the left and right sides of the wiring chamber respectively, two M42 compression nut lead-in devices are installed in front of the wiring chamber, which can be used for external control wiring.

3. The door opening mode of the protective case has a quick opening door structure with a safety mechanical locking device.

a) Release locking before door opening, turn off the switch to cut off the power supply, the vacuum circuit breaker at the high voltage side is tripped, then the next operation can be conducted.

b) After the door is closed, it can be powered.

4. The full Chinese backlit LCD is adopted in the protective case, and parameter setting, data monitoring, historic record query and other operation can be conducted through the operation buttons those are installed on the front door.

1. The elevation height shall not exceed 2,000m;

2. Ambient temperature -5℃ to +40℃ (23ºF to 104ºF);

3. The surrounding relative humidity shall not exceed 95% (25ºC/77ºF);

4. Place without strong vibration and shock;

5. Places where rain, snow, and drips can be prevented;

6. The installation inclination with the horizontal plane shall not exceed 15°.

Contact information

-

About Huaxin

-

Follow Us

-

Share Us

©1996-2023 晋ICP备07500050号 Huaxin Copyright

©1996-2023 晋ICP备07500050号 Huaxin Copyright