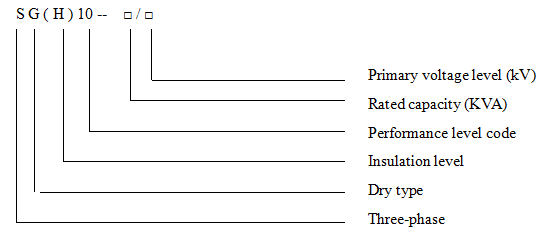

SG(H)10 dry type power transformer

Simply speaking, the dry transformer is the transformer of which the iron core and winding are not immersed in the insulating oil.

It can be divided into two types by structure: (1) winding enveloped with solid insulation (2) winding not enveloped It is used for the fireproof and explosion-proof occasion. For example: general building, subway and so on.

Model description:

Technical parameters:

1. Rated capacity: 100-2500kVA;

2. Rated voltage: primary voltage of 10kV and 6KV

Secondary voltage 0.4kV and others:

3. Rated frequency: 50Hz;

4. Number of phases: 3 phases;

5. Cooling mode: AN/AF;

6. Temperature resistance level of the insulation materials: Level H;

7. For technical performance data and insulation level, see Table 1 and 2.

Table 1 Performance parameters of dry transformer with primary rated voltage of 6kV, 10kV

Rated capacity (kVA)

Voltage combination

Connection unit symbol

Loss

Impedance voltage (%)

No-load current (%)

Primary voltage kV

Primary voltage tapping range %

Secondary voltage kV

No load W

Load W

100

6

10±5

0.4

Dyn11

405

1691

4

1.08

125

±2×2.5

Yyn0

477

1995

0.96

160

549

2290

0.9

200

630

2727

0.84

250

729

2964

0.84

315

891

3734

0.72

400

990

4294

0.72

500

1179

5254

0.72

630

1359

6327

0.6

630

1314

6413

6

0.6

800

1539

7486

0.6

1000

1791

8750

0.6

1250

2115

10431

0.6

1600

2475

12607

0.6

2000

3060

15552

0.48

2500

3600

18487

0.48

Table 2 Insulation level

Rated voltage (kV)

Rated short-term power frequency withstand voltage (kV)

≤1

3

3

10

6

20

10

35

15

38

20

50

35

70

SGH10 series transformer is the insulation system with DuPont NOMEX paper as the main insulating medium. Best electrical performance can be maintained during whole service life of the transformer, and NOMEX paper is not easily aged and has shrinkage resistance, compression resistance and strong elastic force. Therefore, it can ensure that the coil can still maintain close structure and the capability to withstand short circuit after use of the transformer for years. It has high safety and overload capacity, free of flammability, toxic gas, supporting combustion. It is convenient for repair and maintenance, insensitive to humidity, dust and pollution, partial discharge is low, and there is no possibility in 'crack'. The coil adopts the pie type structure and vacuum impregnation process, so as to improve mechanical strength and insulation strength of the coil, and the bottom blowing structure of through-flow fan is adopted for the body, so as to improve heat emission efficiency. It is flexibly designed, and can be made of any specification required according to customer's requirements.

Capacity

L × W × H (mm)

Total weight (kg)

100

1000×620×1080

430

200

1150×620×1145

890

315

1220×620×1280

1290

400

1260×620×1365

1530

500

1280×620×1435

1700

630

1360×700×1540

2190

800

1490×700×1390

2350

1000

1580×720×1480

2840

1250

1670×760×1555

3400

1600

1700×760×1690

3990

2000

1815×890×1690

4410

2500

1815×920×1820

5150

1. Oil-free, pollution-free, flame retardant and fireproof.

2. Low loss, high efficiency and low noise.

3. Small partial discharge capacity (generally below 10PC), high reliability. It can guarantee long-term safe operation, and the life can be up to 30 years.

4. It can resist crack and temperature change, and has high mechanical strength and strong resistance to short circuit capability.

5. The moisture-proof performance is good, it can be in normal operation at the humidity of 100%, and it can be put into operation without drying after stoppage.

6. The independent transformer chamber is not required, it is not required to lift the core for maintenance, and the load bearing beam is not required, which saves floor area for civil engineering; It is oil free, will not generate toxic gas, and will not pollute the environment. The oil sump and other auxiliary buildings are not required, and the construction cost of construction cost is reduced.

7. Installation is convenient without commissioning, and maintenance is almost not required; it is not required to replace and check oil seal, and the operation and maintenance cost is low.

-

About Huaxin

-

Follow us

-

Share us

©1996-2017 晋ICP备07500050号 Huaxin Copyright

©2016-2017 晋ICP备07500050号 Huaxin Copyright