ZPSFG dry type speed regulation transformer -8

The insulation class of ZPSFG series speed control by frequency variation dry transformer is Grade H: the high-tech product NOMEX paper of American DuPont Company is taken as the insulation material; structure and electrical design are conducted with the advanced technology and advanced process. The iron core material of the series product is the high-quality cold rolled grain-oriented silicon steel sheet; the grid side and valve side coil is wound with the high-quality oxygen-free copper conductor, and VPI vacuum pressure lacquer curing process is adopted for treatment. The product performance indicators shall completely conform to requirements in JB/T 8636-1997 industrial standards and IEC61378 international standards.

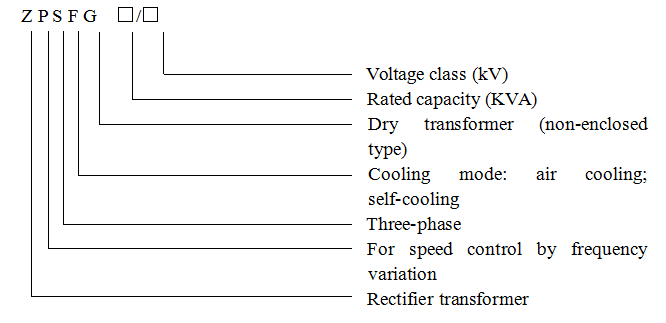

Model description:

Technical parameters:

Product model

Grid side winding

Valve side winding

Short-circuit impedance %

Voltage (kV)

Tapping range

Wiring method

Phase shift coil unit and group number

ZPSFG-250/6

6

±5%

Y or D

Unit number (4 or 7) group number 3

6~8

ZPSFG-300/6

ZPSFG-400/6

ZPSFG-500/6

ZPSFG-680/6

ZPSFG-750/6

ZPSFG-850/6

ZPSFG-1000/6

ZPSFG-1250/6

ZPSFG-1500/6

ZPSFG-1750/6

ZPSFG-2250/6

ZPSFG-2500/6

Product model

Exterior dimensions

Weight

(L × W × H)

(kg)

ZPSFG-250/6

1400×880×1250

1100

ZPSFG-300/6

1450×880×1300

1330

ZPSFG-400/6

1480×880×1300

1580

ZPSFG-500/6

1480×880×1500

1850

ZPSFG-680/6

1500×880×1630

2220

ZPSFG-750/6

1500×880×1650

2400

ZPSFG-850/6

1520×960×1650

2700

ZPSFG-1000/6

1520×1000×1650

3000

ZPSFG-1250/6

1550×1000×1680

3500

ZPSFG-1500/6

1580×1040×1850

3900

ZPSFG-1750/6

1650×1040×1900

4150

ZPSFG-2250/6

1850×1040×1900

5000

ZPSFG-2500/6

1860×1040×1950

5300

1. The high-quality cold-rolled silicon steel sheet is adopted for the iron core. 450 fully-beveled seam, 3-step overlapping, which effectively reduces the no-load loss, no-load current and noise.

2. The grid side and valve side winding shall be Level H insulation, thermal endurance class 1800C, the coil is wound with oxygen-free copper wire wrapped with nomex paper. The special process and structure are adopted, and it is immersed in paint with VPI vacuum pressure for high-temperature curing, which not only improves mechanical strength of the product, but also can enable it to have the overload capability to withstand shock cooling and shock heating.

3. The cooling mode is air cooling, and the thermostat is equipped to realize fan start-stop, overtemperature alarm trip and other functions.

4. There are many pulse waves within a cycle for the valve side winding adopting multi-section phase shift after rectification, which effectively reduces pollution of harmonic wave on power grid.

-

About Huaxin

-

Follow us

-

Share us

©1996-2017 晋ICP备07500050号 Huaxin Copyright

©2016-2017 晋ICP备07500050号 Huaxin Copyright